Propane is a versatile and widely used fuel source that powers everything from residential heating systems and cooking appliances to industrial machinery and vehicles. Its relevance stretches across daily life and industrial applications, making it a crucial component of modern energy solutions. Lately, I’ve written a good amount of articles about propane, propane tanks, and appliances that use propane, and realized I had a question I needed the answer to – “How is propane made? Where does propane come from?”. Down the rabbit hole I went.

In this article I’ll explore the production process of propane, diving into its origins, how it’s processed, and ultimately how it is distributed to consumers. Understanding how propane is made sheds light on its efficiency and environmental impact, and it’s rather interesting to learn about something that we use everyday and what goes behind making it and getting it to my house.

Propane is primarily derived from natural gas processing and crude oil refining, where it exists in a mixture of other hydrocarbon gases and needs to be separated and collected. This process ensures that propane is delivered in its most usable form, either as a liquid or gas, depending on its storage and transportation requirements.

By the end of this article, you’ll have a clear understanding of the entire lifecycle of propane—from its molecular formation to its role as a key energy source globally.

How Propane Is Made

Propane is not just a common fuel; it’s a lifeline for those embracing off-grid living and seeking energy independence. Its significance in the context of off-grid living cannot be overstated—propane is a clean, efficient, and versatile energy source that can be relied upon even in remote areas where connections to natural gas lines are non-existent, or the electric grid is either unreliable or not an option.

One of the key benefits of propane is its portability and storability. Unlike other gases that require complex infrastructure, propane can be compressed into a liquid and stored in tanks ranging from small canisters to large underground tanks. This makes it an ideal solution for energy needs in off-grid settings, where reliability and flexibility are important.

Some Info About Propane Production

When discussing propane and its production, several key terms and concepts are essential to grasp for a comprehensive understanding. Here’s a breakdown of some relevant terms and their significance in the context of propane production and usage:

Key Terms

Hydrocarbons: Propane is a hydrocarbon, which means it is composed of hydrogen and carbon atoms. Specifically, propane’s chemical formula is C3H8, indicating three carbon atoms and eight hydrogen atoms. Hydrocarbons are the primary components of natural gas and crude oil, from which propane is derived.

Natural Gas Liquids (NGLs): Propane is part of a group known as natural gas liquids, which also includes ethane, butane, and pentane. These are all hydrocarbons that are in a gaseous state under natural conditions but can be condensed into liquids for easier transportation and storage. Understanding NGLs is crucial because their separation from natural gas is a critical step in the production of propane.

Fractional Distillation: This is the process used in refineries to separate different components of crude oil and natural gas based on their boiling points. For propane, this process involves cooling the gas until it liquefies, allowing it to be separated from other gases that remain in a vapor state at lower temperatures.

Refining: Refining refers to the various processes that raw crude oil undergoes to be turned into usable products, including gasoline, diesel, and propane. For propane, refining often involves removing impurities and separating it from other hydrocarbons through methods like fractional distillation.

LPG (Liquefied Petroleum Gas): Propane is often stored and transported as part of a mixture known as liquefied petroleum gas, which may also include butane. LPG is significant for its use in heating appliances, cooking equipment, and vehicles, particularly where natural gas is not available.

HGL (Hydrocarbon Gas Liquids): Hydrocarbons such as ethane, propane, normal butane, isobutane, and natural gasoline, along with olefins like ethylene, propylene, butylene, and isobutylene, are all HGL’s. This term includes all natural gas liquids (NGL) and olefins, excluding liquefied natural gas (LNG).

Steps of Propane Production

Propane production involves complex processes and specialized equipment. Here’s a detailed look at the propane production process, outlining the equipment used and the steps. This is a general example of the process for producing propane, some manufactures might use different types of equipment and steps, but this will help give a general idea of how it is made.

1. Extraction and Collection

Natural Gas & Crude Oil Collection: Propane is extracted from underground reservoirs either as a component of natural gas or as a byproduct of crude oil. In natural gas facilities, wellheads collect gas released by drilling, which includes a mix of methane, propane, butane, and other hydrocarbons (sometimes referred to as condensate). During the process of collecting the prior fuel source, propane is part of that fuel and needs to be separated in order to become usable.

2. Separation

Fractionation: Once extracted, the raw mix of gases is transported to processing plants or refineries. Here, it undergoes a process called fractionation. This process involves heating the gas mix in a fractionation tower, causing different hydrocarbons to separate out at various temperatures. Think of how oil and water do not mix, or oils with different weights do not mix, by heating the mix to specific temperatures the different types of gases and liquids can be separated. Propane, due to its unique boiling point (-42 degrees Celsius), separates at a different stage than methane and butane.

3. Purification

Removing Impurities & Water: After separation, propane still contains impurities and moisture that needs to be removed to meet commercial and safety standards. Using dryers and filters, impurities are removed, and the propane is dried to prevent corrosion in storage and transport.

4. Liquefaction

Compressing Gas into Liquid: To facilitate easier storage and transportation, propane is cooled and compressed into a liquid state. This liquefaction process involves refrigeration units that cool the gas, and compressors that apply pressure, turning it into liquid propane (LPG). This allows the transportations of larger amounts of propane, as well as allowing to be stored as a liquid where it boils into a vapor that can be used by appliances.

5. Storage and Distribution

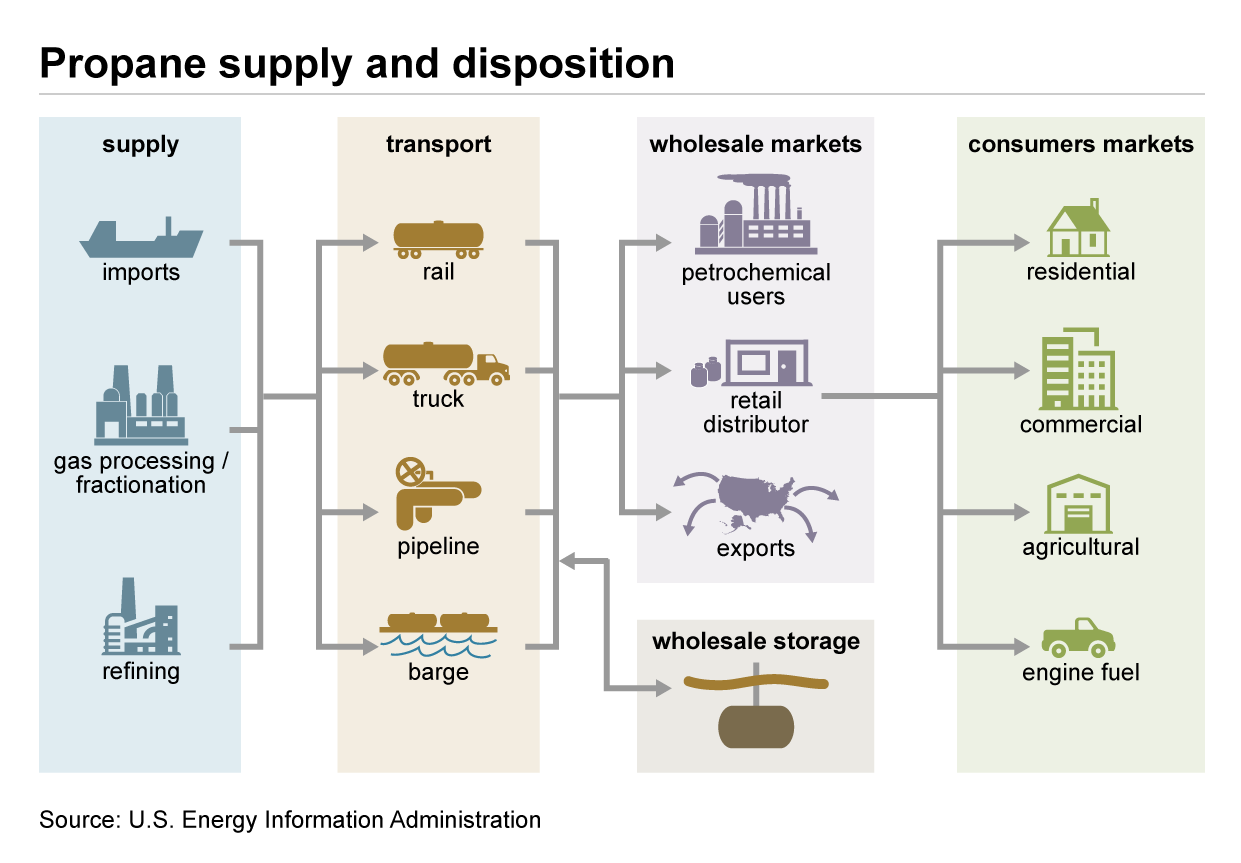

Storage: Once liquefied, propane is stored in large tanks under pressure to keep it in liquid form. It is then distributed via tankers, pipelines, or cylinders to various markets, including residential, commercial, and industrial users.

6. Retail Delivery

Delivery to Consumers: At the consumer level, propane is typically delivered by local distributors who use specialized trucks equipped with portable tanks. These trucks refill residential tanks or exchange cylinders for grills and other small applications.

Additional Info About Propane Production

Here’s some additional info about propane and some tips and insights related to propane usage:

1. Global Production Insights: The United States is one of the largest producers of propane, primarily due to its extensive natural gas and oil refining infrastructure. Significant amounts of propane are also produced in the Middle East and Russia, aligning with global oil and gas production centers.

2. Environmental Impact: Propane is considered one of the cleanest burning fossil fuels. It releases fewer pollutants and greenhouse gases compared to coal or oil, making it a preferred choice for environmentally conscious consumers.

3. Economic Considerations: Propane typically offers a cost-effective solution compared to electricity, especially in remote or rural areas where electric grid infrastructure may be limited or non-existent. However, market prices can fluctuate based on crude oil prices, so it’s wise to monitor these trends if your off-grid setup heavily relies on propane.

4. Versatility and Uses: Beyond heating and cooking, propane is used in agriculture for crop drying, in industry for metal cutting and heating, and even in vehicles as an alternative fuel. Its ability to function in a variety of settings and applications makes it incredibly valuable for diverse needs.

5. Safety Tips:

- Storage: Always store propane tanks upright (See my article on laying propane tanks sideways) and outdoors, away from direct sunlight and in a well-ventilated area.

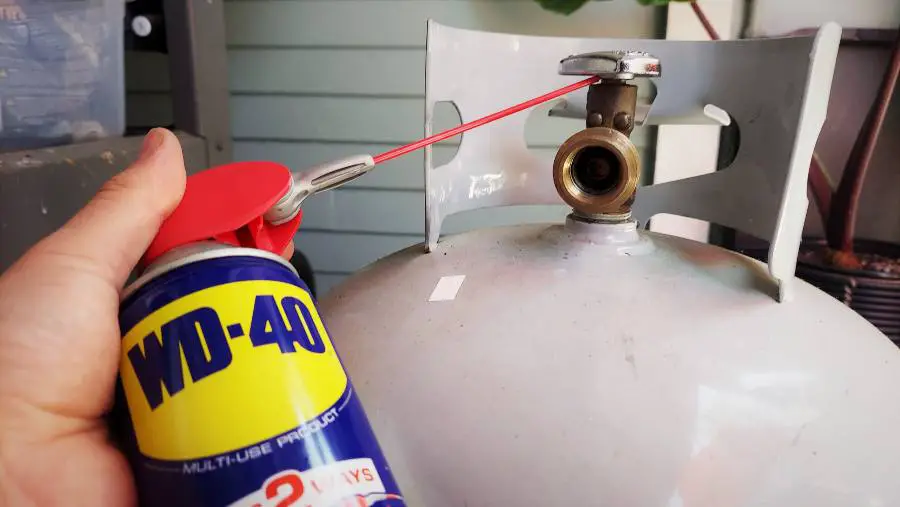

- Leak Checks: Regularly check for leaks using a soapy water solution. Apply it to the tank’s connections and hoses; bubbles will form if there’s a gas leak.

- Installation and Maintenance: Ensure that any propane equipment is installed and regularly serviced by a qualified technician to maintain safety and efficiency.

Differences between Propane and Natural Gas:

- Storage and Transport: Propane can be compressed into a liquid at relatively low pressures and is stored in tanks as a liquid. Natural gas, in contrast, remains a gas under normal atmospheric conditions and requires high-pressure pipelines for distribution.

- Energy Content: Propane has a higher energy content per cubic foot than natural gas, which means it produces more heat per unit, making it more efficient for heating and cooking.

- Infrastructure Requirements: Propane can be used in areas without existing natural gas lines, making it ideal for off-grid living. Natural gas requires a more extensive infrastructure and is less flexible in terms of storage and mobility.

Whether you’re powering a remote cabin or looking for an eco-friendly energy alternative, propane offers a compelling solution that meets a broad range of energy needs.

FAQ

How is propane extracted and processed?

Propane is primarily extracted through two methods: as a byproduct during natural gas processing and as a refined product from crude oil. In natural gas processing, it is separated from other hydrocarbons by cooling the gas mixture until it liquefies. In oil refining, it is isolated during the fractional distillation process, where different hydrocarbons are separated based on their boiling points.

Is propane environmentally friendly?

Yes, propane is considered one of the cleaner fossil fuels. It emits less carbon dioxide and fewer pollutants than coal or oil when burned. This makes it a preferred choice for reducing environmental impact, especially in applications like home heating and cooking.

Can propane be used in areas without natural gas service?

Absolutely. One of the major advantages of propane is its portability. Propane can be compressed and stored as a liquid in tanks, making it an excellent energy source for rural or off-grid areas where natural gas pipelines are not available.

What are the safety considerations for using propane?

Safety is paramount when handling propane. Always store propane tanks outdoors in an upright position and in a well-ventilated area. Regularly check connections and hoses for leaks using a soapy water solution. It’s also crucial to have propane systems installed and maintained by certified professionals.

How long can propane be stored?

Propane has an indefinite shelf life, which means it does not degrade over time. This feature makes it ideal for long-term storage, ensuring a reliable supply for heating or emergency situations.

Is propane more cost-effective than other energy sources?

Propane can be more cost-effective than electricity, especially in off-grid scenarios. It provides a high energy output per unit and is less susceptible to price fluctuations compared to electricity, which can vary significantly with local rates and usage.

Can propane tanks be refilled?

Yes, propane tanks are designed to be refilled, which adds to their convenience and cost-effectiveness. It’s important to have them refilled by a professional to ensure safety and proper handling.

What happens if propane leaks?

If propane leaks, it can pose a risk of fire or explosion if it comes into contact with an ignition source. Propane is heavier than air, so it tends to settle in low areas, which can create pockets of gas. If you suspect a leak, avoid creating sparks or flames, evacuate the area, and contact a professional immediately. Check out my article on how to detect propane leaks and fix them.

By addressing these common questions, you can feel more confident in your understanding of propane’s role as a reliable and sustainable energy source. Whether you’re using it for residential heating, cooking, or even powering vehicles, knowing these basics ensures safer and more efficient use.

Conclusion

In this exploration of how propane is made, we’ve covered its production, and the practical considerations for using it effectively and safely. Propane emerges as a standout choice for energy independence, particularly for those in remote or rural areas. Its efficiency, versatility, and environmental friendliness make it an essential resource for anyone seeking a reliable alternative to traditional energy sources.

Key Takeaways:

- Propane Production: Propane is produced either through natural gas processing or as a byproduct of crude oil refining. Both processes involve separating propane from other hydrocarbons based on its boiling point.

- Environmental Benefits: As one of the cleaner fossil fuels, propane reduces emissions and pollution compared to other common energy sources, supporting a more sustainable lifestyle.

- Versatility and Reliability: Propane’s ability to be stored and transported as a liquid makes it incredibly versatile and reliable, particularly suitable for off-grid living where traditional energy infrastructure may be lacking.

By understanding how propane is made and its benefits, you can better assess its fit for your personal or professional energy requirements. Propane not only offers a dependable source of energy but also aligns with eco-friendly practices, making it an excellent choice for those committed to sustainable living.

Additional Resources and Data Sources

Here are some links to additional resources as well as some references from within the article.

- U.S. Energy Information Administration – Hydrocarbon gas liquids explained

- U.S. Department of Energy – Propane Production and Distribution

I hope this article on how propane is produced has been useful, and please feel free to reach out with any questions, concerns, or comments.

Thank you for reading and God Bless!