Costco is an excellent store for saving money and buying in bulk. Depending on your location, some Costcos offer various services such as Optometry, Pharmacy, Oil Changes, Gas Stations, and more. So you may be wondering, does Costco offer propane services too? Can you refill a propane tank at Costco or have one exchanged?

Well, good news. Costco offers propane refilling at select locations. Out of the ~700 Costco locations, 100 offer Propane services, specifically refilling. While you won’t be able to exchange a propane tank, you can have your tank refilled at these locations, and most locations sell empty propane tanks. Almost all of these locations are located in Canada, so if you’re located in the United States, you’ll want to call your local store to confirm if they refill propane or not.

Below is an interactive map showing all Costco locations that offer propane services.

As I mentioned at the beginning of the article, most Costco locations do not offer propane services. Out of the 700 locations listed on their website, only 100 offer propane services. While some stores do not list propane as a service on their store details page, they may still have propane services. If you do not see your store listed on my verified locations list, it is still worth calling and asking if they offer propane services.

Refilling your propane tanks at Costco is easy, but make sure you have a membership with Costco as you’ll need one in order to have your tanks refilled or purchase new empty ones. Double-check with your location before heading there to ensure they have propane available for refilling your tank.

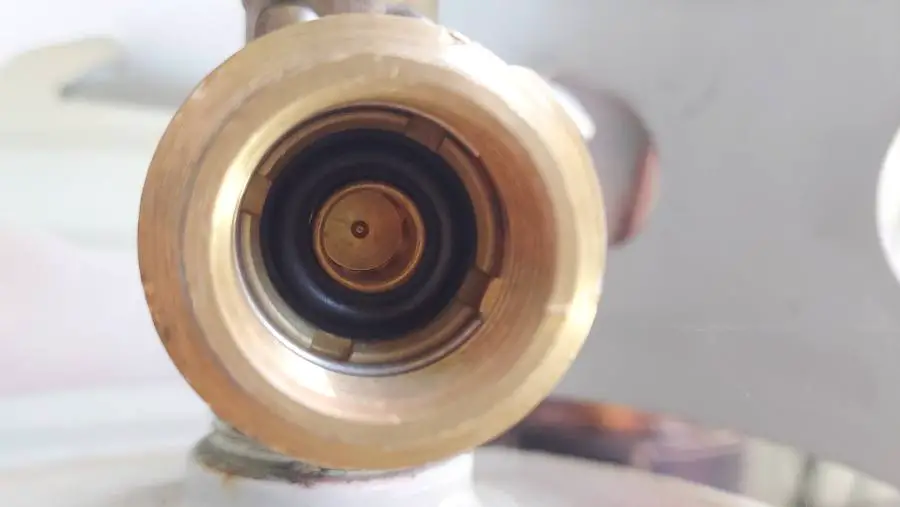

The propane refilling station is typically located outside near the gas station or Tire Depot, or somewhere in the parking lot. You can identify it by the large white propane tank, typically surrounded by red barriers, as pictured above. The propane refilling station will never be inside a warehouse, so do not take your propane tank inside.

Having your propane tanks refilled at Costco is very easy. Simply follow the steps below:

Make sure when you’re traveling with propane tanks, regardless if their empty, to follow basic propane transportation safety. Always make sure the valve is fully closed, and to secure the tank as well as store it in a well ventilated part of the car. Never leave propane tanks in the car for long periods, in high heat, or with the windows up. Never smoke near propane tanks.

Costco propane prices will depend on your specific location, however, most stores refill propane for ~$2.40/gal. This means if Costco fills your entire tank up, which they only fill to 15 lbs (3.7 gallons), it will cost you a total of $8.88 before tax.

Because Costco fills your propane tanks up and doesn’t exchange them, you can bring any brand of propane tank at any fill level. You will only be charged for the amount of propane you get.

Similar to Blue Rhino and Amerigas, Costco only fills their propane tanks to 15 lbs. While this is unfortunate, as they can legally fill it to 20 lbs, the price is still one of the best you’ll find for propane refills.

Are you looking for a Costco propane refill station near you? In total, there are 100 stores that are verified to offer propane services. Below is a list of all locations that have Propane listed as a service on their location details page at Costco.com If you do not see your store on this list, it is still worth calling and checking directly with them.

Click on a state below to jump to that section, or scroll down to see all locations.

Alabama

Mobile #1192

Address: 1450 TINGLE CIRCLE WEST, MOBILE, AL, 36606-2632, US

Phone Number: (251) 308-7030

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Huntsville #356

Address: 1205 N. MEMORIAL PKWY, HUNTSVILLE, AL, 35801-5930, US

Phone Number: (256) 519-2220

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Alberta

Okotoks #1069

Address: 202-104 SOUTHBANK BLVD, OKOTOKS, AB, T1S 0K4, CA

Phone Number: (403) 995-5150

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Rocky View #1076

Address: 300-293020 CROSSIRON COMMON, ROCKY VIEW COUNTY, AB, T4A 0J6, CA

Phone Number: (403) 516-5050

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

St Albert #1157

Address: 1075 ST ALBERT TRAIL, ST. ALBERT, AB, T8N 4K6, CA

Phone Number: (780) 544-2000

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Nisku #1270

Address: 2584 46TH AVE EAST, EDMONTON INTERNATIONAL AIRPORT, AB, T9E 1K2, CA

Phone Number: (825) 319-2061

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

SW Calgary #1381

Address: 12905 BUFFALO RUN BLVD, TSUUT’INA, AB, T3T 0E3, CA

Phone Number: (587) 441-8180

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Lethbridge #160

Address: 3200 MAYOR MAGRATH DR S, LETHBRIDGE, AB, T1K 6Y6, CA

Phone Number: (403) 320-8917

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Red Deer #164

Address: 162 LEVA AVE, RED DEER, AB, T4E 0A5, CA

Phone Number: (403) 347-1424

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Grande Prairie #254

Address: 9901 116 ST, GRANDE PRAIRIE, AB, T8V 5W3, CA

Phone Number: (780) 538-2788

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel

S Edmonton #258

Address: 2616 91 ST NW, EDMONTON, AB, T6N 1N2, CA

Phone Number: (780) 577-1201

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

NW Calgary #543

Address: 11588 SARCEE TRAIL NW, CALGARY, AB, T3R 0A1, CA

Phone Number: (403) 516-3701

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Medicine Hat #593

Address: 2350 BOX SPRINGS BLVD NW, MEDICINE HAT, AB, T1C 0C8, CA

Phone Number: (403) 581-5700

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Arizona

NW Tucson #431

Address: 3901 W COSTCO DR, TUCSON, AZ, 85741-2864, US

Phone Number: (520) 797-1980

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Prescott #466

Address: 3911 E STATE ROUTE 69, PRESCOTT, AZ, 86301-6717, US

Phone Number: (928) 541-2203

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel

N Phoenix #490

Address: 19001 N 27TH AVE, PHOENIX, AZ, 85027-5036, US

Phone Number: (623) 293-4400

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel

British Columbia

Courtenay #1092

Address: 588 CROWN ISLE BLVD, COURTENAY, BC, V9N 0A6, CA

Phone Number: (250) 331-8700

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Prince George #158

Address: 2555 RANGE RD, PRINCE GEORGE, BC, V2N 4G8, CA

Phone Number: (250) 561-0784

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel

Kamloops #161

Address: 1675 VERSATILE DR, KAMLOOPS, BC, V1S 1W7, CA

Phone Number: (250) 374-5336

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Abbotsford #163

Address: 1127 SUMAS WAY, ABBOTSFORD, BC, V2S 8H2, CA

Phone Number: (604) 850-3458

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Langford #256

Address: 799 MCCALLUM DR, VICTORIA, BC, V9B 6A2, CA

Phone Number: (250) 391-1151

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

California

Bakersfield #688

Address: 3800 ROSEDALE HWY, BAKERSFIELD, CA, 93308-6235, US

Phone Number: (661) 852-2643

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel

Lake Elsinore #746

Address: 29315 CENTRAL AVE, LAKE ELSINORE, CA, 92532-2212, US

Phone Number: (951) 253-6030

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Poway #775

Address: 12155 TECH CENTER DR, POWAY, CA, 92064-7156, US

Phone Number: (858) 848-2451

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Car Wash

Florida

Kendall #1023

Address: 13450 SW 120TH ST, MIAMI, FL, 33186-7393, US

Phone Number: (305) 964-4227

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

S Orlando #1235

Address: 4696 GARDENS PARK BLVD, ORLANDO, FL, 32839-2171, US

Phone Number: (407) 586-7221

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

E Orlando #185

Address: 3333 UNIVERSITY BLVD, WINTER PARK, FL, 32792-7428, US

Phone Number: (407) 681-2119

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Georgia

Fort Oglethorpe #1083

Address: 100 COBB PKWY, RINGGOLD, GA, 30736-8566, US

Phone Number: (706) 891-2579

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Cumming #1175

Address: 1211 BALD RIDGE MARINA RD, CUMMING, GA, 30041-8484, US

Phone Number: (470) 239-6610

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Manitoba

E Winnipeg #153

Address: 1499 REGENT AVE W, WINNIPEG, MB, R2C 4M4, CA

Phone Number: (204) 654-4214

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

S Winnipeg #549

Address: 2365 MCGILLIVRAY BLVD, WINNIPEG, MB, R3Y 0A1, CA

Phone Number: (204) 487-5100

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

W Winnipeg #57

Address: 1315 ST JAMES ST, WINNIPEG, MB, R3H 0K9, CA

Phone Number: (204) 788-4415

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Montana

Kalispell #745

Address: 2330 US HIGHWAY 93 N, KALISPELL, MT, 59901-2547, US

Phone Number: (406) 758-2500

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Nevada

SW Henderson #1320

Address: 3411 SAINT ROSE PKWY, HENDERSON, NV, 89052-4570, US

Phone Number: (702) 803-7044

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

New Brunswick

Saint John #1055

Address: 300 RETAIL DRIVE, SAINT JOHN, NB, E2J 2R2, CA

Phone Number: (506) 635-5300

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Fredericton #1090

Address: 25 WAYNE SQUIBB BLVD, FREDERICTON, NB, E3C 0G8, CA

Phone Number: (506) 460-4100

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Moncton #1345

Address: 140 GRANITE DR, MONCTON, NB, E1H 0K6, CA

Phone Number: (506) 317-0423

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Newfoundland and Labrador

St Johns #1324

Address: 75 DANNY DR, ST. JOHN’S, NL, A1H 0N4, CA

Phone Number: (709) 701-8929

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

North Carolina

Garner #1587

Address: 7800 FAYETTEVILLE RD., RALEIGH, NC, 27603, US

Phone Number: (984) 810-5030

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Greensboro #339

Address: 4201 W WENDOVER AVE, GREENSBORO, NC, 27407-1908, US

Phone Number: (336) 291-4010

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Charlotte #359

Address: 500 TYVOLA RD, CHARLOTTE, NC, 28217-3504, US

Phone Number: (704) 501-2403

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Winston Salem #361

Address: 1085 HANES MALL BLVD, WINSTON SALEM, NC, 27103-1310, US

Phone Number: (336) 970-2300

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Wilmington #635

Address: 5351 GINGERWOOD DR, WILMINGTON, NC, 28405-3091, US

Phone Number: (910) 798-3250

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Raleigh #645

Address: 2838 WAKE FOREST RD, RALEIGH, NC, 27609-7840, US

Phone Number: (919) 755-2801

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Nova Scotia

Halifax #519

Address: 230 CHAIN LAKE DR, HALIFAX, NS, B3S 1C5, CA

Phone Number: (902) 876-7788

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Dartmouth #551

Address: 137 COUNTRYVIEW DR, DARTMOUTH, NS, B3B 0E7, CA

Phone Number: (902) 481-7635

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Ontario

Ancaster #1105

Address: 100 LEGEND CRT, ANCASTER, ON, L9K 1J3, CA

Phone Number: (905) 304-0344

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Oshawa #1128

Address: 130 RITSON RD NORTH, OSHAWA, ON, L1G 0A6, CA

Phone Number: (905) 404-4050

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Barrhaven #1263

Address: 4315 STRANDHERD DR, NEPEAN, ON, K2J 6E5, CA

Phone Number: (613) 714-0913

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Orillia #1265

Address: 625 UNIVERSITY AVE, ORILLIA, ON, L3V 0Y7, CA

Phone Number: (705) 418-1706

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Stoney Creek #1273

Address: 1330 SOUTH SERVICE RD, STONEY CREEK, ON, L8E 5C5, CA

Phone Number: (289) 335-4820

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Gloucester #1362

Address: 1405 BLAIR TOWERS PLACE, GLOUCESTER, ON, K1J 1A5, CA

Phone Number: (613) 691-7607

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Niagara Falls #1414

Address: 7500 PIN OAK DRIVE, NIAGARA FALLS, ON, L2H 2E9, CA

Phone Number: (365) 447-0200

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Markham #151

Address: 1 YORKTECH DR, MARKHAM, ON, L6G 1A6, CA

Phone Number: (905) 477-5718

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane

Ajax #159

Address: 150 KINGSTON RD E, AJAX, ON, L1Z 1E5, CA

Phone Number: (905) 619-6677

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

N Oshawa #1591

Address: 100 WINDFIELDS FARM DR E, OSHAWA, ON, L1L 0R8, CA

Phone Number: (289) 316-4489

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Brampton #162

Address: 100 BISCAYNE CRES, BRAMPTON, ON, L6W 4S1, CA

Phone Number: (905) 450-9300

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Barrie #252

Address: 41 MAPLEVIEW DR E, BARRIE, ON, L4N 9A9, CA

Phone Number: (705) 728-2350

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane

Burlington ON #253

Address: 1225 BRANT ST, BURLINGTON, ON, L7P 1X7, CA

Phone Number: (905) 336-6714

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Sudbury #257

Address: 1465 KINGSWAY, SUDBURY, ON, P3B 0A5, CA

Phone Number: (705) 524-8255

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane

Newmarket #510

Address: 18182 YONGE ST, EAST GWILLIMBURY, ON, L9N 0J3, CA

Phone Number: (905) 954-4733

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Kitchener #512

Address: 4438 KING STE, KITCHENER, ON, N2P 2G4, CA

Phone Number: (519) 650-3330

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Etobicoke #524

Address: 50 QUEEN ELIZABETH BLVD, ETOBICOKE, ON, M8Z 1M1, CA

Phone Number: (416) 251-2832

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

N London #530

Address: 693 WONDERLAND RD N, LONDON, ON, N6H 4L1, CA

Phone Number: (519) 474-5301

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Diesel, Oil Change

S Mississauga #531

Address: 3180 LAIRD RD, MISSISSAUGA, ON, L5L 6A5, CA

Phone Number: (905) 828-3340

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Kingston #533

Address: 1015 CENTENNIAL DR, KINGSTON, ON, K7P 3B7, CA

Phone Number: (613) 549-2527

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Windsor #534

Address: 4411 WALKER RD, WINDSOR, ON, N8W 3T6, CA

Phone Number: (519) 972-1899

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Scarborough ON #537

Address: 1411 WARDEN AVE, SCARBOROUGH, ON, M1R 2S3, CA

Phone Number: (416) 288-0033

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Nepean #540

Address: 1849 MERIVALE RD, NEPEAN, ON, K2G 1E3, CA

Phone Number: (613) 727-4786

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Kanata #541

Address: 770 SILVER SEVEN RD, KANATA, ON, K2V 0A1, CA

Phone Number: (613) 270-5550

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

E Markham #545

Address: 65 KIRKHAM DR, MARKHAM, ON, L3S 0A9, CA

Phone Number: (905) 201-3502

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Vaughan #547

Address: 71 COLOSSUS DR, WOODBRIDGE, ON, L4L 9J8, CA

Phone Number: (905) 264-8337

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Peterborough #591

Address: 485 THE PARKWAY, PETERBOROUGH, ON, K9J 0B3, CA

Phone Number: (705) 750-2600

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Richmond Hill #592

Address: 35 JOHN BIRCHALL RD, RICHMOND HILL, ON, L4S 0B2, CA

Phone Number: (905) 780-2100

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Pennsylvania

Lancaster PA #317

Address: 1875 HEMPSTEAD RD, LANCASTER, PA, 17601-5671, US

Phone Number: (717) 396-8460

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Quebec

Drummondville #1127

Address: 105 RUE ROBERT-BERNARD, DRUMMONDVILLE, QC, J2C 0P6, CA

Phone Number: (819) 473-7575

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Saint-Hubert #1359

Address: 1000 BOUL SAINT-BRUNO, SAINT-BRUNO, QC, J3V 6P4, CA

Phone Number: (579) 314-0046

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Sherbrooke #1367

Address: 3800 BOUL MGR-FORTIER, SHERBROOKE, QC, J1L 0J6, CA

Phone Number: (873) 500-5544

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Anjou #1446

Address: 9401 BOULEVARD DES SCIENCES, ANJOU, QC, H1J 0A6, CA

Phone Number: (514) 493-4814

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Anjou Bus Ctr #1447

Address: 7373 RUE BOMBARDIER, ANJOU, QC, H1J 2V2, CA

Phone Number: (438) 858-5451

Services Offered: Gas Station, Propane

Quebec #503

Address: 440 RUE BOUVIER, QUEBEC, QC, G2J 1E3, CA

Phone Number: (418) 627-5100

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Laval #505

Address: 2999 AUTOROUTE LAVAL 440 OUEST, LAVAL, QC, H7P 5P4, CA

Phone Number: (450) 686-7420

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Sainte-Foy #516

Address: 3233 AV WATT, QUEBEC, QC, G1X 4W2, CA

Phone Number: (418) 656-0666

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Trois Rivieres #518

Address: 3000 DES RECOLLETS, TROIS-RIV OUEST, QC, G9A 6J2, CA

Phone Number: (819) 693-5758

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Brossard #521

Address: 9430 BOUL TASCHEREAU, BROSSARD, QC, J4X 2W2, CA

Phone Number: (450) 444-4466

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Terrebonne #525

Address: 870 MONTEE DES PIONNIERS, TERREBONNE, QC, J6V 1N9, CA

Phone Number: (450) 657-4353

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

St Jerome #529

Address: 1001 BOUL JEAN-BAPTISTE-ROLLAND, SAINT-JEROME, QC, J7Y 4Y7, CA

Phone Number: (450) 476-9000

Services Offered: Food Court, Gas Station, Optical Department, Tire Service Center, Propane, Oil Change

Boucherville #532

Address: 635 CHEMIN DE TOURAINE, BOUCHERVILLE, QC, J4B 5E4, CA

Phone Number: (450) 645-2631

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Chicoutimi #536

Address: 2500 BOUL TALBOT RR4, CHICOUTIMI, QC, G7H 5B1, CA

Phone Number: (418) 696-1112

Services Offered: Food Court, Optical Department, Tire Service Center, Propane, Oil Change

Gatineau #542

Address: 1100 BOUL MALONEY OUEST, GATINEAU, QC, J8T 6G3, CA

Phone Number: (819) 246-4005

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Boisbriand #546

Address: 3600 AVE DES GRANDES TOURELLES, BOISBRIAND, QC, J7H 0A1, CA

Phone Number: (450) 420-4500

Services Offered: Food Court, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

Candiac #556

Address: 60 RUE STRASBOURG, CANDIAC, QC, J5R 0B4, CA

Phone Number: (450) 444-3453

Services Offered: Food Court, Gas Station, Optical Department, Pharmacy, Tire Service Center, Propane, Oil Change

South Carolina

Greenville #1005

Address: 1021 WOODRUFF RD, GREENVILLE, SC, 29607-4108, US

Phone Number: (864) 297-2560

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Myrtle Beach #338

Address: 1021 OAK FOREST LN, MYRTLE BEACH, SC, 29577-9795, US

Phone Number: (843) 839-6604

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Charleston #360

Address: 3050 ASHLEY TOWN CENTER DR, CHARLESTON, SC, 29414-5664, US

Phone Number: (843) 460-2003

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Tennessee

Farragut #1116

Address: 10745 KINGSTON PIKE, KNOXVILLE, TN, 37934-3002, US

Phone Number: (865) 218-7700

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Puerto Rico

Carolina #335

Address: 1185 AVE 65 INFANTERIA, SAN JUAN, PR, 00924-3403, US

Phone Number: (787) 999-7230

Services Offered: Food Court, Gas Station, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

E Bayamon #363

Address: 125 CALLE A, BAYAMON, PR, 00959, US

Phone Number: (787) 993-9303

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

W Bayamon #364

Address: PR-2 KM 15.5, BAYAMON, PR, 00961, US

Phone Number: (787) 474-6930

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane

Caguas #365

Address: 200 AVE RAFAEL CORDERO PR#30, CAGUAS BAIROA WARD, PR, 00725-4302, US

Phone Number: (787) 653-6930

Services Offered: Food Court, Hearing Aids, Optical Department, Pharmacy, Tire Service Center, Propane